Advancing the art and understanding of fine woodworking!

Salvaging a “Bad Board” at the August Guild Meeting

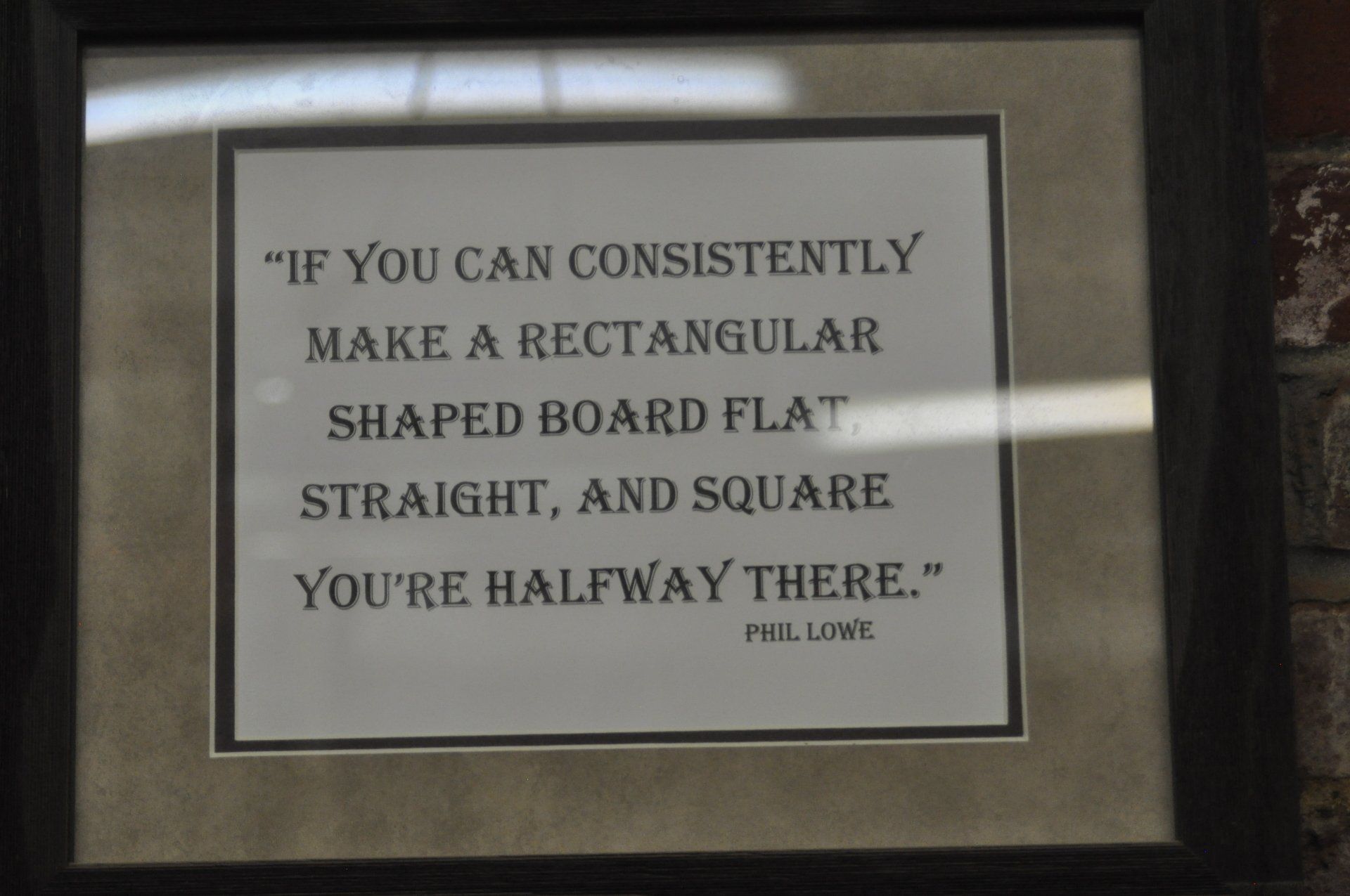

This sign shown above hangs on the wall behind the workbench in Phil Lowe’s shop. At our August meeting Roger Moister and Jim Milam will show you first how to recognize a board that is not flat, straight and square, and then to take such a board and remedy its ills. The skill sets and tools required for these tasks will be discussed and demonstrated. If you have a “bad board” (of reasonable size) that is so, twisted, bowed, or cupped that it is headed for the wood stove, bring it. And if time permits, you can make a run at salvaging it so it can be incorporated in your next project.

And don't forget Show 'N Tell !

Methods of Work by Marc Adams

at the July 9th Guild Meeting

At the July meeting, the Guild program featured a DVD by Marc Adams on Sharing Secrets, Methods of Work. Roger Moister, our Librarian, introduced the program and promoted the use of the more than 200 DVDs that are available for checkout to our members. Roger brings all of these DVDs to each meeting at Woodcraft and is happy for you to look through them to find any that interest you, that you can "borrow" for the next month. Roger also has prepared a list of DVDs that relate to the top 9 interest categories that our members have voted on. He also listed DVDs that relate to the Marc Adams video.

Marc Adams has built a woodworking school in an Indiana cornfield where it is guaranteed that you can have an enjoyable adventure in woodworking. The DVD we featured had loads of good tips that many of us did not know about. The Video focuses on design and layout, and shaping wood.

There are so many good ideas that it is hard to even remember all of them. Dealing with that problem, Tom Melcher cranked up his old Guttenberg press and came up with a booklet that outlined the portions of the video that we saw, along with pages for notes. Thanks Tom !

Marc recommends making scale models of proposed projects to help in visualization before the project is begun. Time saving tricks for making hand-cut dovetails were discussed. John Jones added to the DVD by showing how to make the grain match at all four corners of a box. Use of the Golden Rectangle in design was explained.

Thanks to the Program Committee for an excellent Meeting !

President’s Message - August 2018

Gary Fader

Machine to Woodworker: “Are you listening?”

So, you're preparing to use a woodworking machine; maybe it’s a bandsaw, a table saw, or a belt/disk sander. You’re safety conscious, so you turn on the area air filter and put on your safety glasses, your dust mask, and your hearing protection. After some basic checks, on goes the dust collector and then the machine itself. Wow, think of all that background noise and sound filtering from your ear muffs. It’s a wonder you can hear any warning signs!

But what about that evolving ticking from the bandsaw, or the flapping of a fraying drive belt, or the rubbing from a loosening sanding disk, or the slight wobbling of a loosening table saw blade? Even if you have heard such noises, have you chosen to continue working because in just a few more moments, the task will be finished, and then you can figure out what’s wrong?

As the saying goes: “How do I know this?” Snap goes my ticking bandsaw blade! Fortunately, they typically stop in place while the drive wheels spin down. But it’s frightening and could cause injury.

The message here is one of vigilance. We need to be ever conscientious, and listening and watching for signs of potential trouble. There’s a reason they make big STOP buttons and place them for quick access. The job will still get finished after the problem is resolved.

On a similar subject, I had a very valuable lesson when I first started woodworking with potentially harmful machines. A close friend and I both bought radial arm saws at the same time. He was a high-energy type, who moved around quickly, often taking actions before thinking clearly. One night, his wife called from a local hospital where several of his fingers were being stitched and bandaged; the result of contacting a spinning dado blade. Lesson learned, slow down and think twice about what you’re about to do.

Woodworking is such a wonderful, challenging, and satisfying endeavor. The list of “don’ts” could fill books. Just don’t forget to work safely!

Guild Charity Toy Making - 2018

The Guild is again making toys for hospitalized children. They will be given to children during the Winter holidays. Several members are already cutting out puzzles. Parts for toy trains will be cut out at a special meeting on September 13, at 1:00 PM at Woodcraft. That afternoon, we will be cutting components, sanding parts, squaring up & gluing puzzles, and finally branding them with the Guild Logo.

We certainly would enjoy and appreciate your participation. Please E-mail your desire to help out at Woodcraft on Sept. 13th at 1:00 PM to Nuane Neely, the Guild Charitable Projects Director

nneely@mindspring.com

In October, our regular 2nd Monday meeting is usually cancelled because of the October Mini-Symposium, to be held at Suwanee Lumber Company on October 13. However, this year we will meet at Woodcraft at 7:00 PM on the second Monday, October 8, and will assemble the toys using the parts made on September 13. We had a great time and fellowship last year, and hope you will be able come and help with the final toys assembly this year!

SAPFM Annual Meeting

By Jim Milam

The Society of American Period Furniture Makers (SAPFM) holds a meeting every year and the 2018 version took place in Old Sturbridge Village, a two hour drive west of Boston. The 4-day weekend was so jam packed with museum visits and woodworking instruction that there was no time to see the sights in the 18th century setting where much of the activities took place.

Day one began with a bus trip to the Museum of Fine Arts in Boston where Phil Lowe, Robert Mussey, and Al Breed pointed out nuances of 18th century furniture by the likes of carver Samuel McIntire, and Federal period furniture makers John & Thomas Seymour. We also had an extended session studying a marvelous tall clock, ca 1800, attributed to Nathan Lumbard, who made furniture in what is now Old Sturbridge Village. Our after dinner speaker that night was none other than Norm Abram, who is a member of OSV’s board of directors.

Day two was consumed by two lectures and three workshops (demonstrations emphasizing how-to techniques of Chippendale and Federal Period design and construction techniques).

1. Al Breed demonstrated carving a Newport concave shell before a small, intimate audience. He seems to obtain near-perfect results without concentrating; taking questions while he works - - astonishing to one who has trouble simultaneously walking and chewing gum.

2. Phil Lowe lectured on how he believed Boston craftsmen would have made lunette and other bandings in the late 18th and early 19th centuries.

3. My good friend Will Neptune gave an hour-long lecture on proportion and symmetry in architecture and furniture, focusing on the work of Connecticut cabinetmaker Eliphalet Chapin. A 50+ page article on this subject (authored by Will and Steve Brown) appears in the 2017 issue of

American Furniture Journal (an annual publication for museum academics).

4. Jennifer Anderson made a presentation on the mahogany trade, touching on mahogany’s many aliases, and concentrating on the Louis Thompson Mahogany Company of Philadelphia.

I highly recommend her book Mahogany, The Costs of Luxury in Early America. It is a history lesson on mahogany logging, shipping, ship building, and how the mahogany trade was interwoven with other commerce beginning in the late 1600’s.

5. Randy Wilkinson spoke on wood anatomy, focusing on identifying wood species in period furniture. With more than 80,000 species in the world, Randy highlighted several notable examples of lesser-known woods misidentified as mahogany.

The after dinner speaker was Brock Jobe (Professor Emeritus of American Decorative Arts at Winterthur Museum and board member of Old Sturbridge Village) who spoke about OSV’s efforts to re-establish a working cabinet shop there.

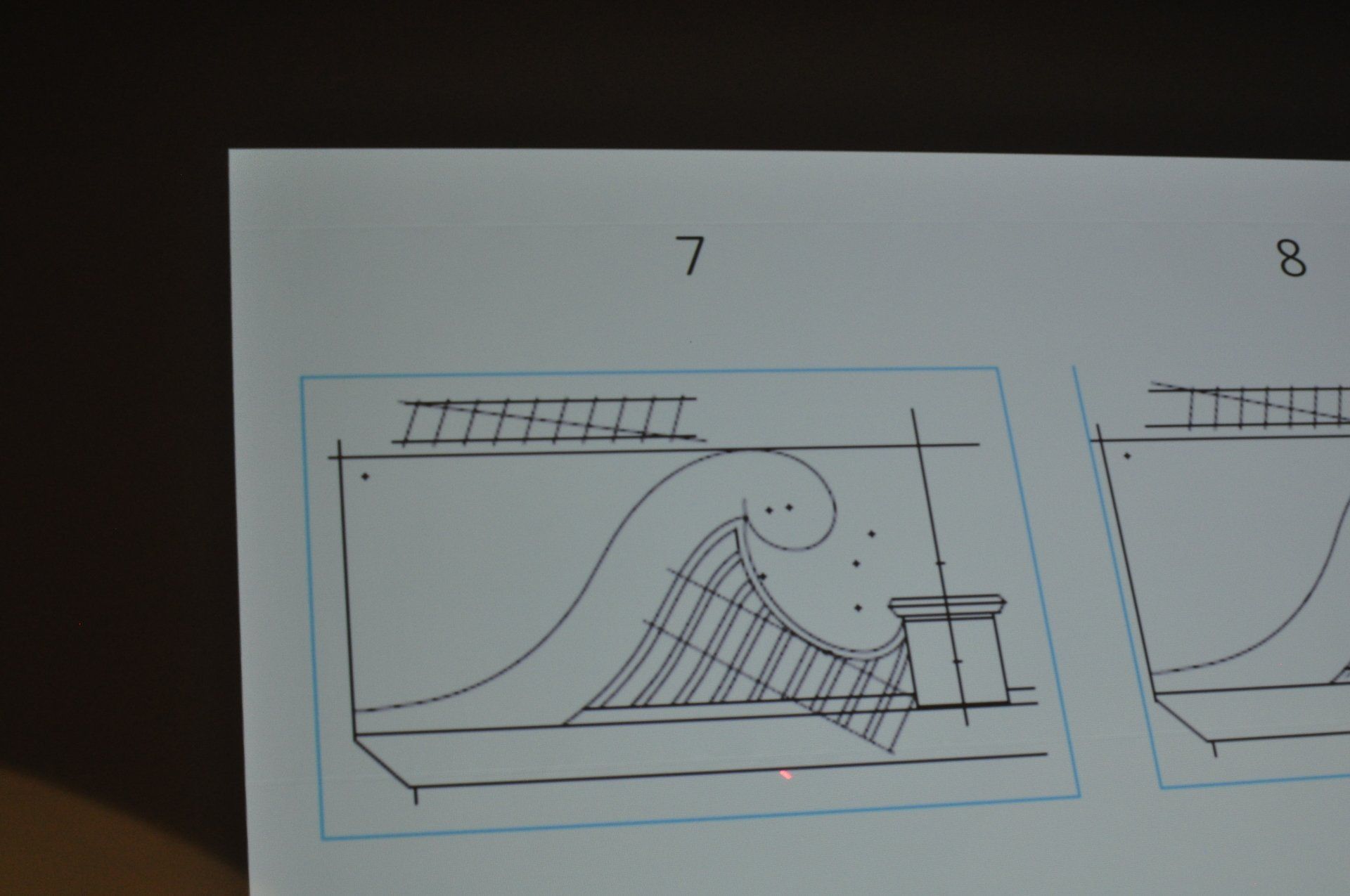

Day three was very much like the previous day - - heavier on the lectures and less demonstrations. Three back-to-back lectures by Al Breed on a highboy, Pembroke table, and documents chest, all made by Newport craftsman John Townsend (described by Al as a perfectionist); Phil Lowe on his techniques for reproducing six Federal chairs for Peabody Essex Museum; and Will Neptune imparting further on 18th century furniture design and its adherence to Greek and Roman proportional relationships and geometry.

Then there were optional workshops. I chose to listen in as Matt Bickford demonstrated the use of his hollows and rounds. Matt makes his living hand-making reproduction wooden molding planes and I understand that his backlog of orders will take years to fill. And then I sat in on a lecture/demonstration on making patriotic bandings and paterae by Michael Wheeler, a Boston cabinetmaker with decades of experience in Federal period work.

Finally, Brock Jobe and Christie Jackson jointly lectured on the life and furniture of Nathan Lumbard - - the same Nathan Lumbard mentioned above. Brock, like Norm Abram, is also on the board of Old Sturbridge Village. Allow me to recommend another book, this one by Brock Jobe and Christie Jackson titled Crafting Excellence: The furniture of Nathan Lumbard and His Circle. It is a masterpiece highlighting the craftsmanship of a rural Massachusetts cabinetmaker.

Day Four was another off site visit - - this time to Peabody Essex Museum in Salem, MA. The museum is normally closed on Monday, but due to Phil Lowe’s influence there, we were treated to a tour of several houses on the premises, and a lengthy visit in the museum proper where Phil expounded on pieces made by Thomas Seymour and Nathaniel Gould. This was followed by a short drive to Phil’s shop where he fed us lunch and then spoke for an hour on his construction technique for making diamond muntins for period casework doors.

This was a whirlwind 5 days (including travel) and I thoroughly enjoyed every minute soaking in nuance details of a subject about which I am passionate. I took more than 600 photos, 4 of which are included below.

Using Hand Planes

By Guild Member Charles Downey - Class taken at Highland Woodworking

Purpose of my taking this Class: I purchased a Wood River No. 7 Plane for leveling a breakfast tabletop that I’m building for my son. To keep the plane iron (blade) sharp, I bought a waterstone system, including a honing guide. After sharpening and using the new plane, I noticed faint marks on the wood like someone had slid a four-legged pot across it. I sharpened and rounded the corners of the iron with no success of stopping the appearance of new marks. I even lightly sanded the sole of the plane but that didn’t work either.

The Class: All students were encouraged to bring their favorite plane with them to class. There were two other students in the class. One had an inexpensive Ace Hardware plane and the other had an old plane that he bought at a garage sale while I had my Wood River No. 7.

Mr. Jim Dillion did an excellent job in teaching the usage of hand planes. Jim first gave us a brief introduction on the history and different types of planes. He quoted Mr. James Krenov, who stated the plane is “the cabinetmaker’s violin”.

After that, he had us check our planes for squareness and flatness. Then he instructed us to take the planes apart to include removing the frog while looking for rust, broken or missing parts. Then we gave all parts a good cleaning and removed any rust.

Problem Found and Solved: From there we examined the iron, chip-breaker, and lever cap. Jim noticed on my iron the cutting edge had two very small chips in it. He took me over to the compact sharpening machine and showed me how to use it while explaining the importance of getting the angle of the cutting edge correct. I followed his instructions and removed the chips.

Conclusion: We put our planes back together with Jim’s instructions. We were given a piece of poplar for our final test. My plane passed with excellence. I had never planed a piece of wood with such ease with thin shavings that you could see through, and there were no marks! Problem solved.

In addition, Jim gave us many helpful tips and techniques on how to us our planes, which is for another story.

Finally, I want to express my appreciation to the Guild for the opportunity to attend this class!

*This article is by a Guild member who, at a recent Guild Meeting raffle, won this partially-funded class.

Show 'n Tell

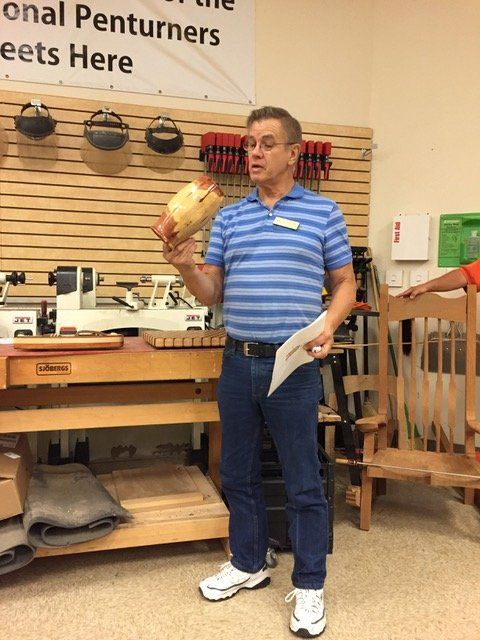

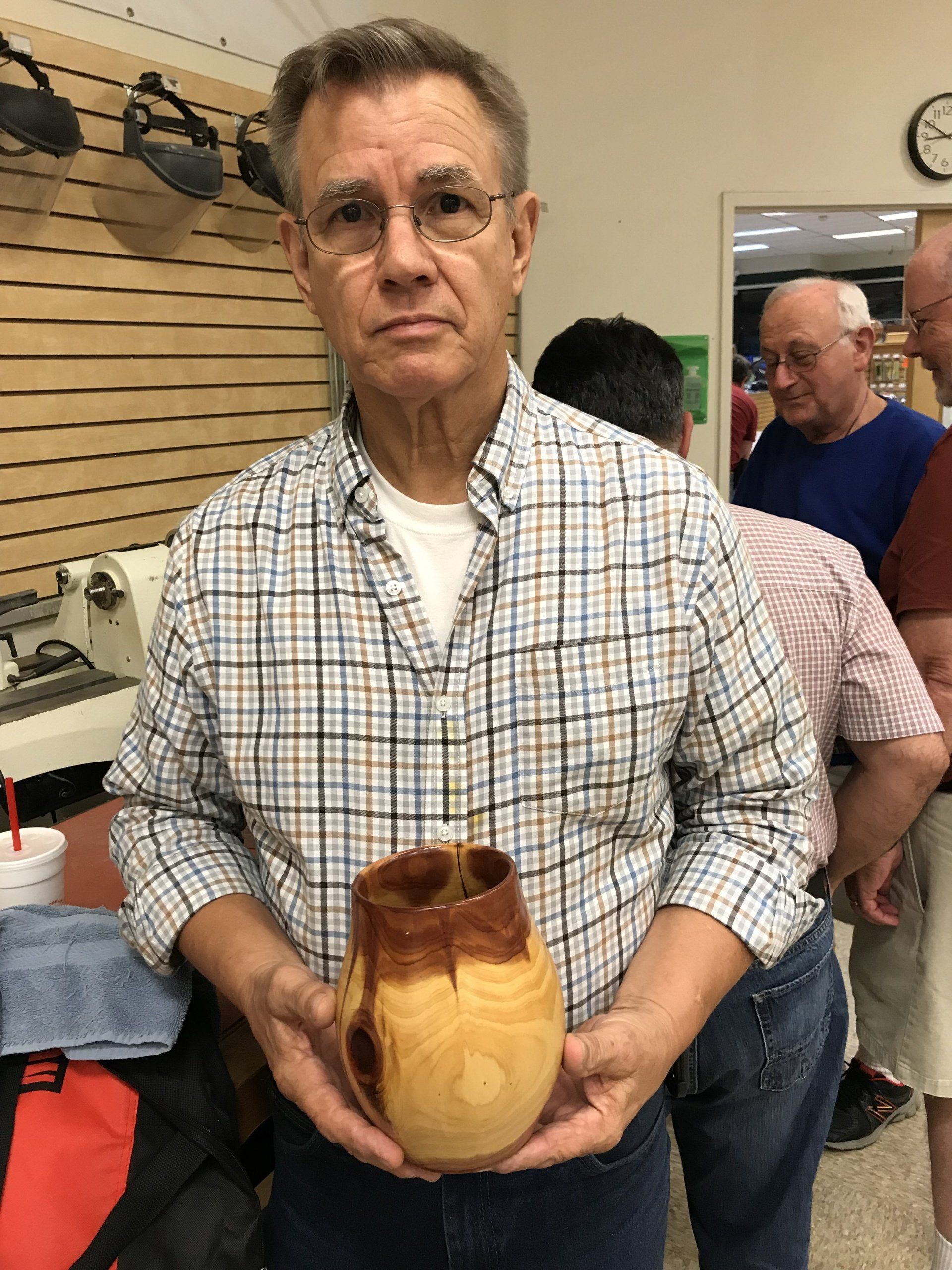

Five Guild members shared their skills at the July 9th Meeting at Woodcraft.

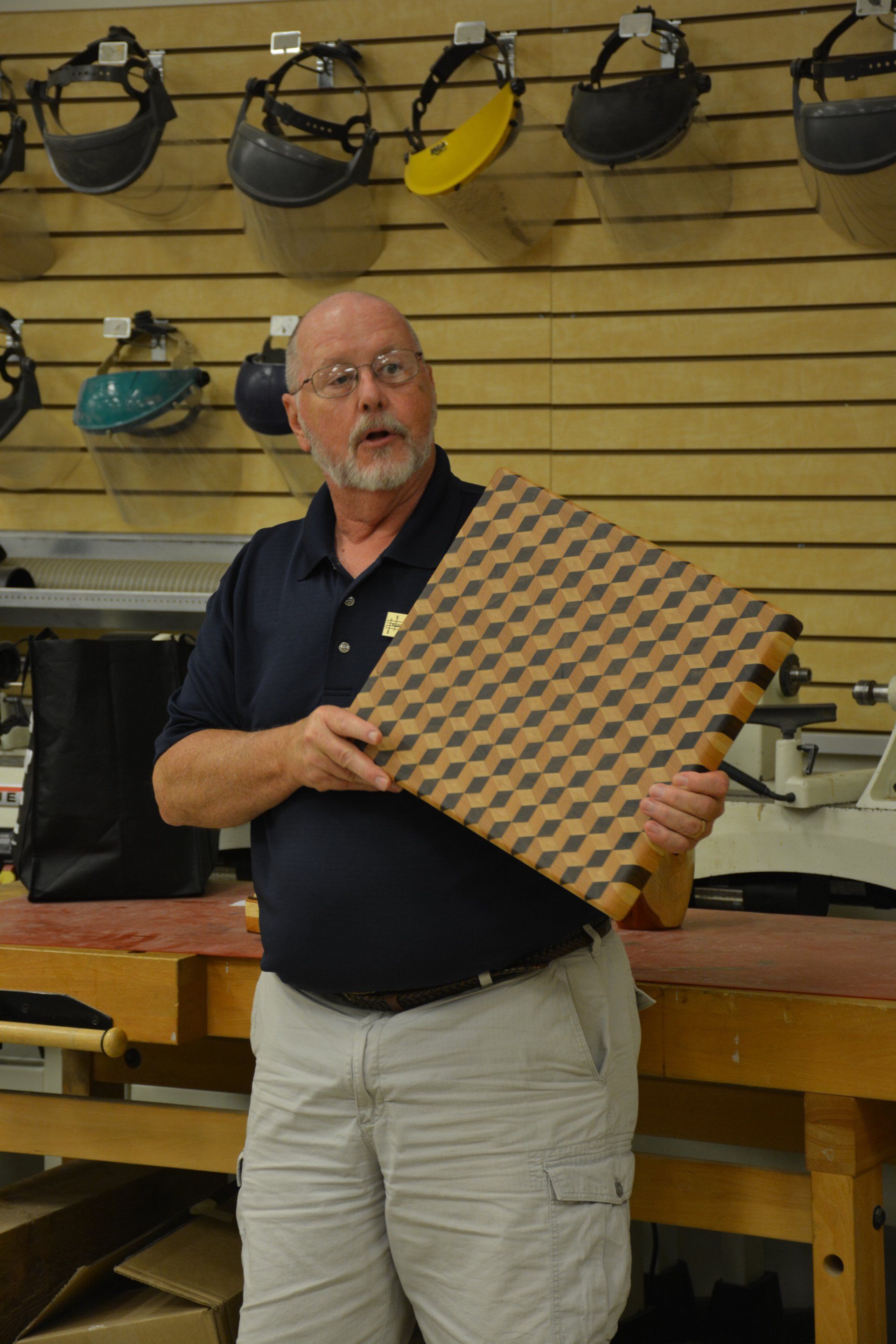

Gary Fjeld 3-D End Grain Cutting Board

Jessie Johnson Turned Vessel

Kevin Woods Turned Bowls and 1 Vase

Gary Fader Bathtub Boats

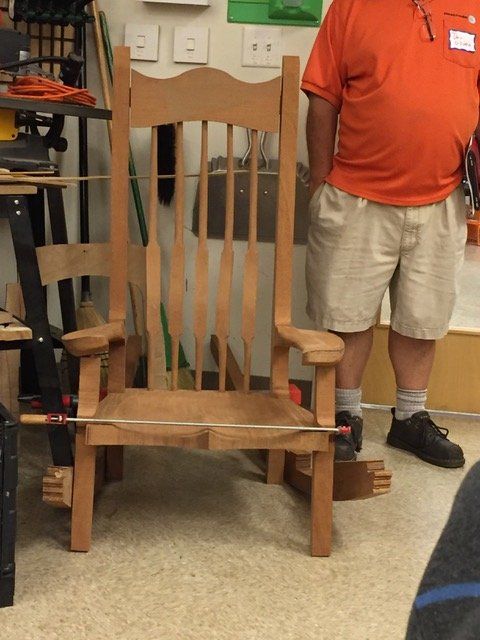

Earl Dabney Rocker

Beautiful Work, Gentlemen!

Bring Your Project(s) to Show 'N Tell

at the August 13th Meeting

Turners' Group

PLEASE NOTE:

The "3rd Monday" Turners' Group at Rockler in Kennesaw will not meet this Summer, but possibly will resume in the Fall.

Stay Tuned (and Sharp)

Woodworkers’ Guild of Georgia

Upcoming Events

Monday, August 13

Monthly Meeting Woodcraft - Roswell 7:00 PM

"Bad" Board Reclamation

August 22-25

International Woodworking Fair Convention and Trade Show

World Congress Center - Atlanta (Biennial Visit)

Monday, September 10

Monthly Meeting Woodcraft - Alpharetta 7:00 PM

Miniature Woodworking with Kelli Risoli

Thursday, September 13

Charity Toys Parts Fabrication Woodcraft - Alpharetta 1:00 PM

Monday, October 8

Charity Toys Assembly Woodcraft - Alpharetta 7:00 PM

Saturday, October 13

Fall Mini-Symposium Suwanee Lumber - 9:00 AM

Cabinet Making with Paul Fussel

Free Demonstrations

Rockler 6690 Roswell Road / Sandy Springs

&

425 Ernest Barrett Pkwy / Kennesaw

Aug 11: 11:00 Rockler Cross Lap Jig

Aug 18: 11:00 Bench Dog Hand Planes

Aug 25: 11:00 Rockler Convertable Benchtop Router Table

Sep 1: 11:00 Bandsaw Techniques

Woodcraft 8560 Holcomb Bridge Road / Roswell

Aug 11: 1:00 Finishing Choices: Water Vs Oil/Brush Vs Spray

Aug 18: 1:00 Router Selection

Aug 25: 1:00 CNC in the Woodshop

Sep 1: 1:00 Bandsaw Tune-Up

For Sale:

Cyclonic Dust Collector (Oneida Air Systems)

- 1.5 HP 115V 17 amps system (can be wired for 220V)

- Original owner’s manual

- 35 gal dust collection drum with air tight seal

- Free standing floor model 7 feet tall

- all metal construction

- 6 inch air intake port

- Made in USA

- Original price $1700

- Asking $750

Call Rene Bilodeau 470-899-8353

The Guild Board of Directors

Gary Fader President 770-977-7271

Art Sanders Treasurer 678-472-9117

Nuane Neely Community/Charitable Projects 770-922-1933

John Champion Woodworking Show 2018 404-307-0817

Tom Melcher Patron Sponsors 770-851-1098

Jim Milam Spring Symposium 2018 404-255-2314

Tom Risoli Website Administrator I 678-513-0887

Steven Sheppard Website Administrator II 770-316-7160

John Jones Vice-President, Secretary 678-576-7265

Jim Milam Member at Large 404-255-2314

Roger Moister Librarian 404-355-5033

John Nielsen Membership 770-434-3812

Joe Rodriguez Scholarships 224-659-2225

Mark Haugland Newsletter 678-294-8043

Jim Wright Audio Visual/Member at Large 770-973-4692

John Jones Communications 678-576-7265

Ken Gregg Program Committee Chairman 678-799-6157

Support Your Woodworkers’ Guild of Georgia Patron Sponsors

Proof of Guild membership is required by

Patron Sponsors

that offer discounts. Your membership card can be printed from our Guild website. Login and go to Guild Info > Members Only, and click on Membership Card. If you would like to pick up your membership card at the next Guild meeting, email us

with your member name.

CAG Lumber - CAG Lumber is known for the largest selection of live edge slabs and unusual woods from all over the world.

We sell on the net, not the gross, so you take home what you pay for with no added on or hidden fees. We can saw your logs, kiln dry, resaw lumber, plane, straight line, and glue up ready. We are large enough to handle your needs and small enough to give one on one personal service. Guild members show membership card to receive 10% off most items, except items on clearance or discounted. Check out our web site, we stock a lot more than is listed. Website

Fintech Abrasives - For over 25 years, Fintech Technologies has been fabricating belts, sheets, rolls and other abrasives. They also have extensive experience with the application of the newest materials in coated abrasives. Family owned and operated in Belding, MI, Fintech is a highly respected company that takes pride in its excellent product quality, unmatched customer service, and superior technical support. Guild members are welcome to order products, as well as contact them with questions. Call them at 1-888-223-8768.Website

Highland Woodworking - Providing fine woodworking tools and project supplies since 1978, Highland defines itself as a learning community. The store has attracted nationally known teachers and authors including Tage Frid, Sam Maloof, Michael Dunbar, Rude Osolnik, Toshio Odate, Dale Nish, Mark Duginske and many others in Highland’s ongoing program of seminars and workshops. We have some great woodworking class opportunities coming up at Highland Woodworking! We have classes and seminars every week that include basic sharpening techniques, turning, finishing, project builds, and much more! Click to see our class schedule.

Their catalog of fine woodworking tools and workshops is available online, or visit its fully-stocked store at 1045 N. Highland Avenue in Atlanta, 30306. 404-872-4466. Website

Peach State Lumber Products - We are dealers of high grade/cabinet quality hardwoods, plywood, softwood, veneer and also carry a full line of cabinet grade plywood and turning blocks. We welcome small quantity orders and have a retail sales area open to the public. We also carry Hettich brand hinges and drawer slides. We have hardware screws and pocket hole screws. We now have live edge slabs in multiple species, great for bar tops, mantels, etc. Show your Guild membership card to receive their 500 b.f. price on any qualifying purchase.

Located at 4000 Moon Station Road, Kennesaw, 30144. 770-428-3622. Website

Peachtree Woodworking Supply -

Peachtree is a producer and retailer of high quality woodworking products with a goal of providing the woodworker with the hard to find tools and accessories. They stock over 6,000 different woodworking items. Those items include a wide selection of abrasives, books, DVD’s, clamps, router bits, glue, t-track, dust collection, and much more. Peachtree also carries the major brands. The store is located at 6684 Jimmy Carter Blvd., Suite 100, Norcross, GA 30071, 770-458-5539. Store Hours: Mon – Fri 9 am.- 5 p.m., Sat 9 am - 3 pm. Website

Redmond Machinery - Specializes in new and used woodworking and metal working machinery in a 25,000 square foot showroom. We stock machinery, accessories, and supplies from top-name manufacturers. Bargain hunters, check out our large inventory of used and scratch and dent machinery and accessories. We are a source for older American made Powermatic and Delta parts. We invite Guild members to stop by to visit us. We are located at 58 Weldon Rd., Palmetto, GA 30268, 770-683-7297 or 800-428-9898 Website

Rockler Woodworking and Hardware

- (Two Locations) - Rockler began as a mail order woodworking supply company and today the retail chain stretches across the United States. Our magazine, Woodworker’s Journal, is dedicated to offering plans, techniques, product reviews and tips to woodworkers. Our goal is to be your go-to woodworking resource. Please mention you are a Guild members BEFORE your purchase to receive 10% OFF everyday (normal exclusions apply).

We invite you to visit us at 6690 Roswell Road in Sandy Springs 404-460-1000, OR 425 Ernest W. Barrett Pkwy in Kennesaw 678-383-0087. Hours are Monday-Friday 9 am to 7 pm, Saturday 9 am to 6 pm, and Sunday 11 am to 4 pm. On Saturdays we have free demos. Website

Suwanee Lumber Company – Is a specialty hardwood supplier for custom cabinet and furniture makers as well as the general public. Suwanee features hardwood lumber with matching plywood and other materials to make every project a work of art. Please show your Guild membership card when shopping to receive Level 4 pricing (1,000 b.f. pricing).

Their location is 540 Satellite Blvd. in Suwanee, GA 30024. 770-945-2102. Website

Woodcraft - (Two Locations) – Has been a woodworker's favorite source for quality hand and power tools, equipment and supplies (including wood). Cabinet makers, wood turners, carvers and woodworkers in general rely on our friendly, experienced staff that is always available to help with the selection of tools and supplies as well as provide helpful advice on individual projects. We have fully equipped classroom facilities. Guild members receive 10% OFF qualifying purchases during our monthly Guild meeting or Symposiums at the Alpharetta store.

Stop by our store at 8560 Holcomb Bridge Road in Alpharetta, GA 30022, 770-587-3372 OR our West side Store at 351 Thornton Road in Lithia Springs. GA 30122, 770-485-5636. Website

The Woodworkers' Guild of Georgia

Newsletter is published monthly, and is provided to all Guild members.

The Newsletter, and its archived copies, is posted on our website.

It is also available 24/7 on our Newsletter URL wwgga.tlehs.com

If you have questions, wish to contribute an article, place an ad, etc., please use Feedback form below

The Guild welcomes everyone interested in fine woodworking to join. Annual membership dues are $45.00,

which can be paid at the monthly meeting (2nd Mondays) or mailed to:

Woodworkers' Guild of Georgia / P.O. Box 1323 / Woodstock, GA 30188

You may also pay dues using PayPal at wwgofga.com

Enjoy Your Newsletter. We Welcome Your Feedback.